"Diversität leben - eigentlich ist das für uns alle Alltag. Aber diese Diversität wollen und müssen wir auch im Arbeitsleben noch konsequenter abbilden. Davon profitieren wir, Diversität ist heute Grundvoraussetzung für Erfolg!" Das Statement kommt von Herzen. Sehen Sie selbst!

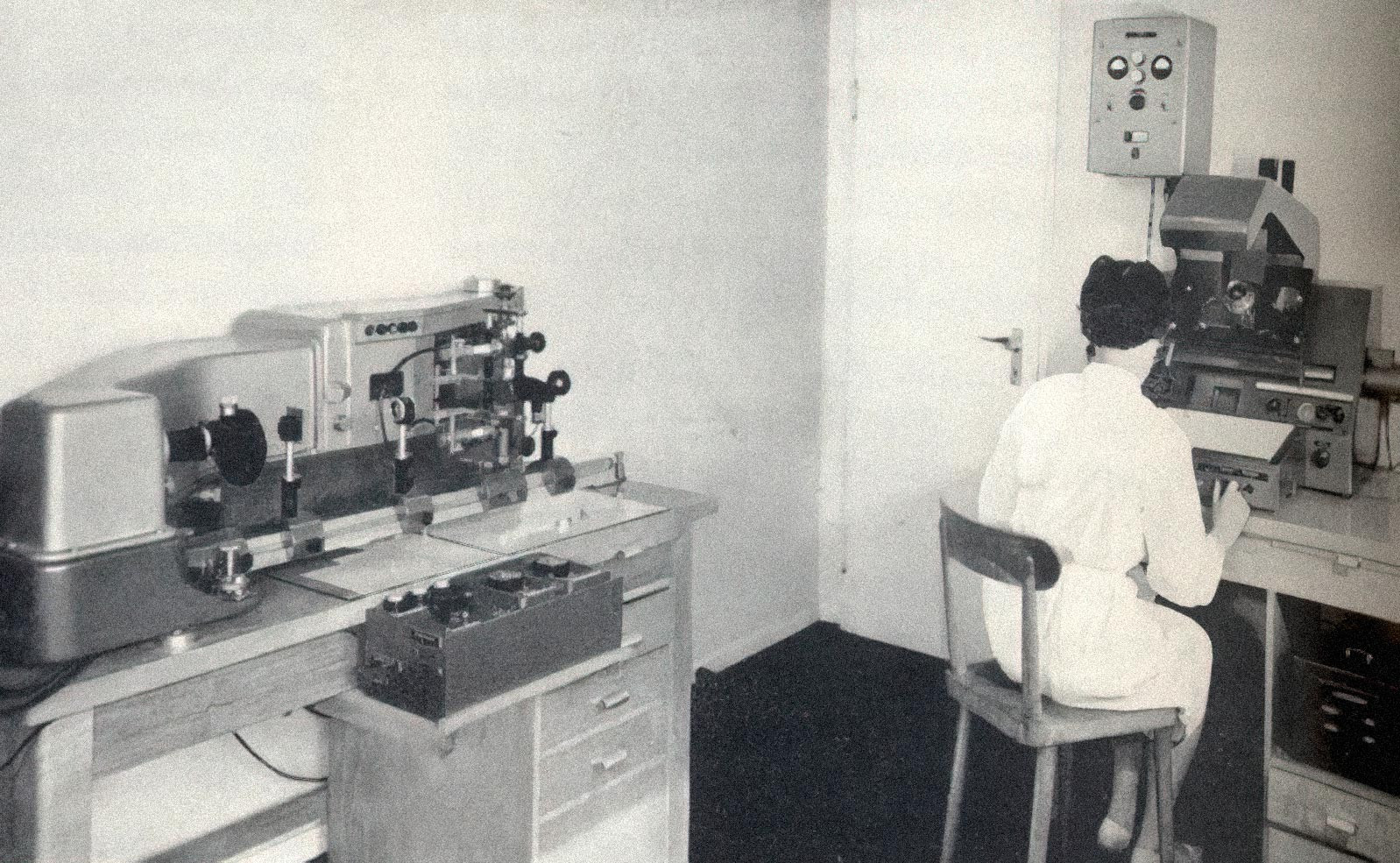

To this day, it remains the case that inspections alone cannot sufficiently minimise possible risks. As early as 1921, when a predecessor of RWTÜV still operated under the name of the Mines Association (Zechen-Verein) in Essen, a department for laboratory work was established in addition to the steam boiler department, electrical engineering department, and department for heat and power management.

The Essen research facility of the Zechen-Verein soon gained great recognition throughout Germany and also enabled cooperation with universities such as RWTH Aachen and the Haus der Technik in Essen. This was explicitly encouraged by management. Research was carried out on materials, construction drawings, and welding, operating and testing methods.

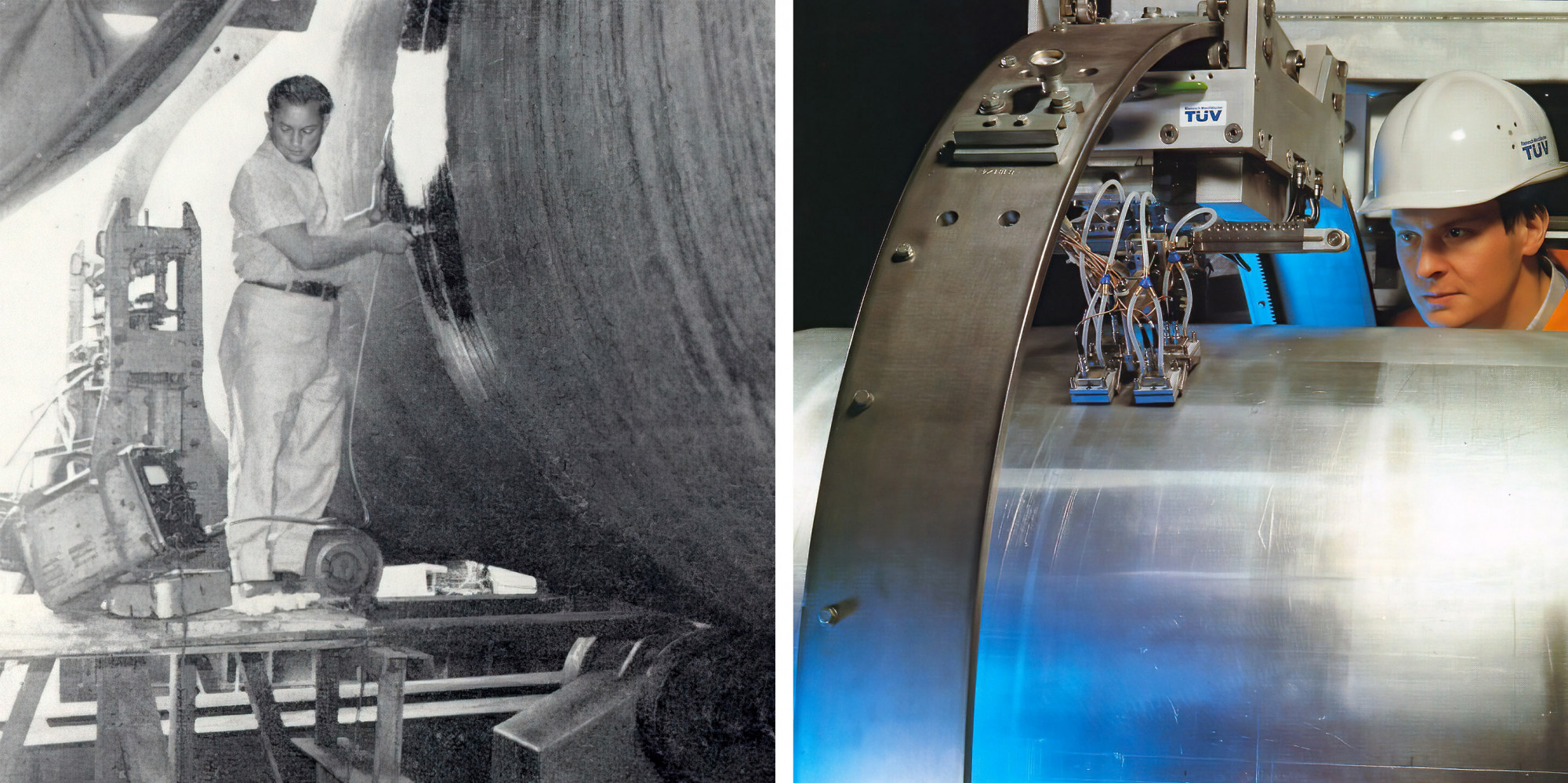

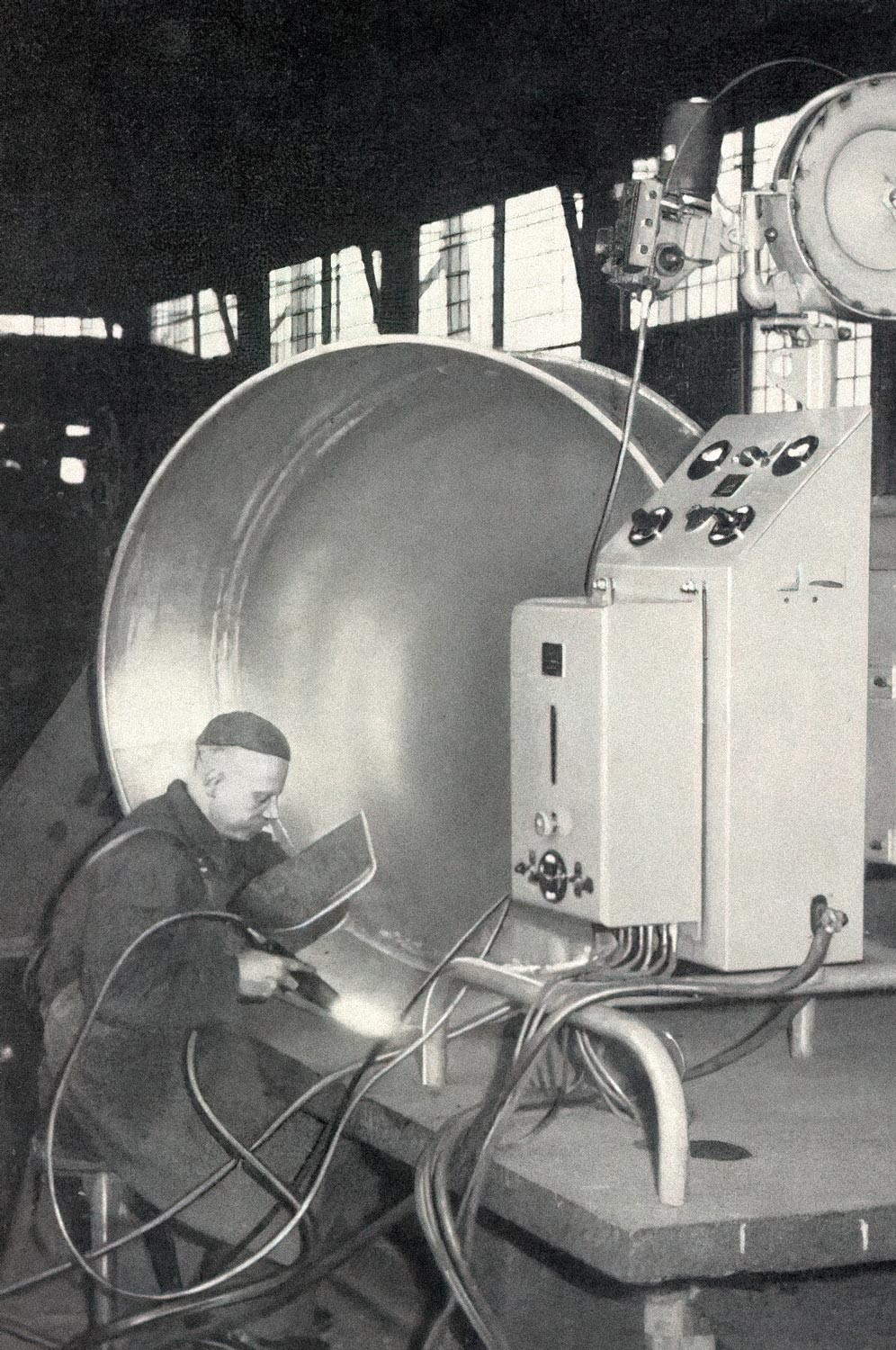

The Essen and Siegen branches of the RWTÜV predecessors were pioneers, especially in non-destructive testing. Even before the war, they had their own X-ray facilities for the inspection of weld seams and castings; in 1953, this method was replaced by the more reliable ultrasound. For the first large nuclear power plants, in 1968 RWTÜV experts even developed a concept for a remote-controlled procedure for recurring inspections in a radioactive environment. This was not only largely adopted in the guidelines of the German Reactor Safety Commission, but also attracted much attention abroad.

Heat and power management has always been a focus of research activities. Starting with flue gas analysis – read with a magnifying glass – to measure absorption values during boiler firing, research was constantly carried out on further ways of saving energy and improving economic efficiency.

As early as the 1950s, a considerable effort was put into developing suitable measuring methods for fine dusts, into immission forecasting, and into analyses for recording dust constituents. The investigation results were used in the laboratories, for example, to calculate chimney heights – a special area of expertise for RWTÜV.

Parallel to the Heat and Power Management department, in 1921 the “Laboratory for the Investigation of Coal” started to make a name for itself. It successively acquired expertise in the analysis of all kinds of fuels, ashes and slags, as well as insulating and refractory building materials. Metal analysis and metallographic research was conducted in the laboratory for metallic materials.

From 1926, the gas analysis laboratory had experts in exhaust gas testing, for example to monitor carbon monoxide, sulphur dioxide or other pollutants, which were also investigated for carcinogenic or other harmful potential.

While it may seem hard to believe from today’s perspective, during the 1990s the environmental protection market actually experienced a sharp downturn. The industrial and commercial sectors cut their investments in protective measures to a necessary minimum – for example concerning dust and harmful gas emissions. As a consequence, RWTÜV parted with some laboratories and equipment – mainly in chemistry – for economic reasons. But never with its thirst for knowledge!

In the course of the 2004 merger between TÜV Hannover/Sachsen-Anhalt, TÜV Nord e.V. and RWTÜV AG, the described areas of activity were transferred, and today are offered by the TÜV Nord Group. RWTÜV AG holds a 36.1% stake in TÜV Nord AG.