"Diversität leben - eigentlich ist das für uns alle Alltag. Aber diese Diversität wollen und müssen wir auch im Arbeitsleben noch konsequenter abbilden. Davon profitieren wir, Diversität ist heute Grundvoraussetzung für Erfolg!" Das Statement kommt von Herzen. Sehen Sie selbst!

From the beginning, the inspectors at DÜV and later TÜV never regarded themselves as mere observers, but always as designers with a creative spark. Carrying out their own research activities was a matter of course, not only to constantly refine and improve the inspection process, but because they wanted their input to enhance safety and improve quality in the development and planning stages.

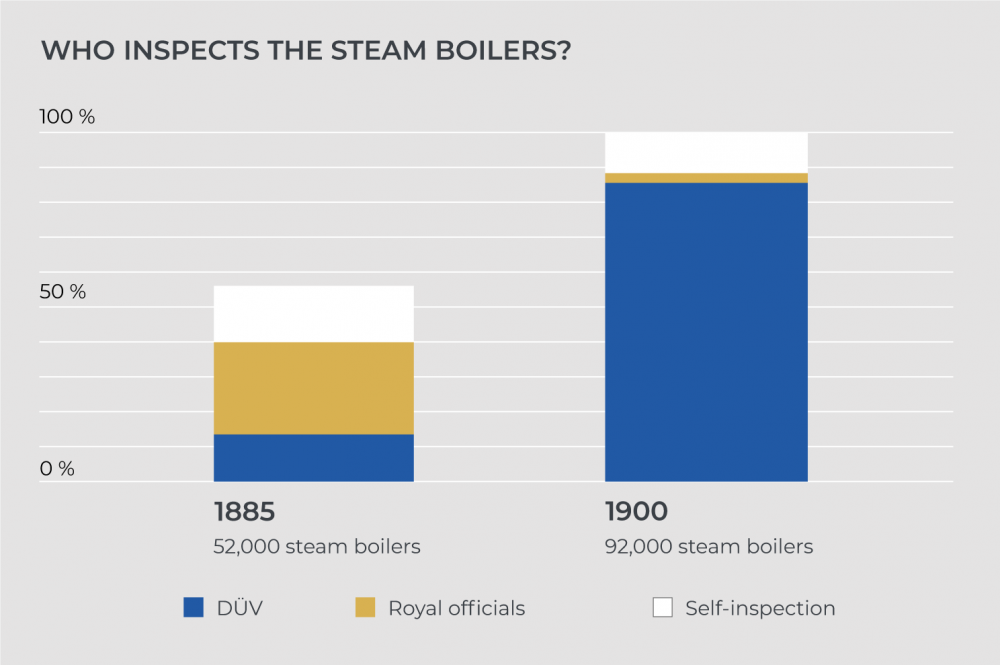

The number of DÜV associations in Germany grew rapidly. The first standards for the construction of steam boilers were drafted in 1881, and a central association of Prussian DÜV organisations was founded in 1884. Official authorisation was then granted to carry out acceptance tests for steam boilers on behalf of the state. The Reich Trade Ordinance finally allowed DÜV officials to carry out internal and external inspections, water pressure tests and acceptance tests even for non-members of the DÜV association.

While the industrial revolution in Great Britain was driven by the textile industry, in Germany it was mining that played the prominent role. Especially in the Ruhr valley and surrounding regions, the history of DÜV is closely linked with that of the mines. In 1900, the “DÜV der Zechen im Oberbergamtsbezirk Dortmund zu Essen (Ruhr) e.V.” was formed from an association that had existed since 1858. Over time, a total of six DÜV associations, including DÜV zu Siegen e.V., were merged into this new “Zechen-Verein”, the “Colliery-Association”.

A sharp drop in the number of incidents sent out a clear signal: the DÜV model was working very successfully!

Soon, in subsequent design and technology developments, DÜV engineers were involved from the outset. Their expertise ensured high safety standards and reliable quality. From now on, they were partners in technical innovations – such as the introduction of electricity, which was cleaner and more readily available – and in parallel they developed suitable approval and testing procedures.

With the Prussian Cost Law of 1905, DÜV was given responsibility not only for steam boilers but now also a wider range of inspection tasks including the installation, testing and maintenance of elevators, motor vehicles and their drivers, pressure vessels for gases, mineral water apparatus, acetylene plants, and other electrical installations. DÜV becomes TÜV!